Nova’s highly sensitive metrology and advanced process control technologies provide unique, scalable solutions to address the semiconductor industry’s materials metrology challenges.

As integrated circuits and their components continue to scale, innovative materials and compounds are introduced at an increasing rate to the production process. This evolution has many implications. For example, layers used to fabricate advanced devices are becoming thinner, and there is a need to precisely characterize minute changes in material properties to stabilize the R&D stage process and ensure effective process control in high volume manufacturing.

Each layer deposited on a device can range from a single atomic layer to several nanometers in thickness. Small variations in composition and material properties or miscalculation of even a few atoms can negatively impact both device functionality and manufacturing yield. It is also important for manufacturers to implement process controls based on ultra-thin film thickness, dopant concentration, implant uniformity and other material properties such as contamination, stress, strain, crystallinity, and phases.

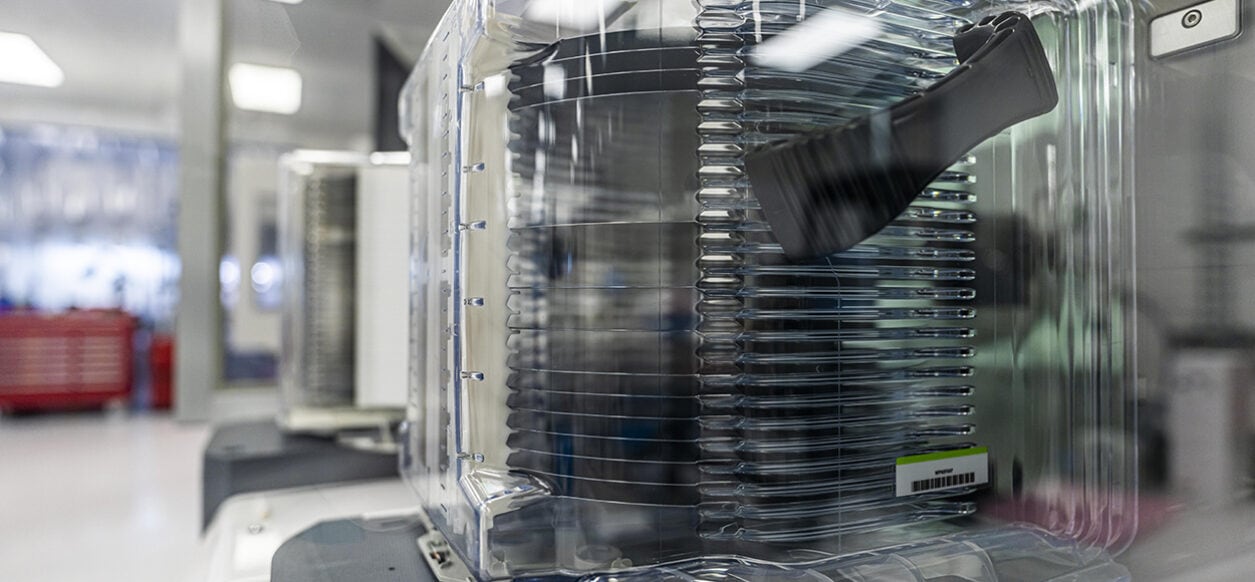

Nova brings to the fab a broad spectrum of technologies previously available only in laboratories, such as X-ray photoelectron spectroscopy (XPS), X-ray fluorescence (XRF), secondary ion mass spectrometry (SIMS), and Raman spectroscopy. These technologies provide extensive information by measuring a wide range of applications. Nova’s materials metrology solutions eliminate the need for lab-based reference metrology, leading to reduced manufacturing downtime and faster time to market as well as enhanced data quality and higher yield.

Innovative Materials Metrology Technologies for Advanced IC Devices